To use cable sleeves, first organize your cables, then cut the sleeve to the required length and apply it. Cable management is simplified with sleeves, providing both protection and a neater appearance.

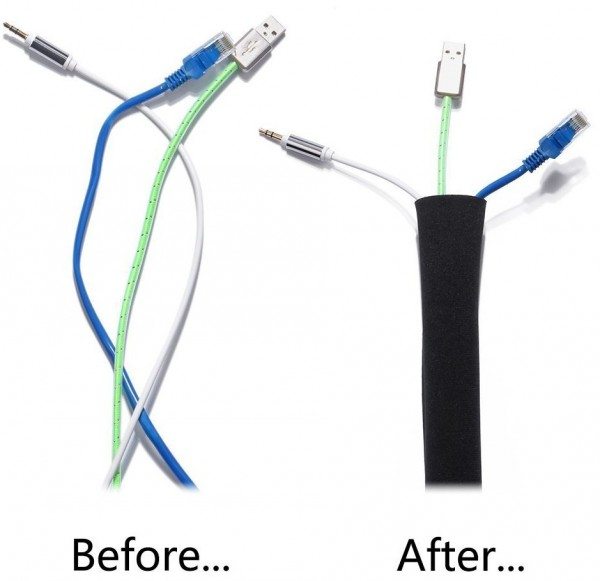

Effective cable management is essential for both safety and aesthetics. Cable sleeves are a popular tool that helps in tidying up wires and preventing tangling. These flexible sheaths come in various materials like neoprene, PET, and heat-shrink tubing, accommodating different cable bundles.

By encasing multiple wires, they reduce clutter and minimize the risk of damage. Users value the straightforward application process, making it a breeze to keep home and office spaces organized. Durability and easy maintenance are key benefits of opting for cable sleeves. This not only streamlines setups but also contributes to an orderly environment, enhancing the performance and longevity of your cables.

Credit: the-gadgeteer.com

The Importance Of Cable Management

The Importance of Cable Management cannot be overstated. Imagine your workspace or entertainment center with tangled wires strewn across. Not only does it look messy, but it also poses safety risks and makes routine maintenance an ordeal. Cable management, and specifically the use of cable sleeves, can transform this chaos into an organized and functional space. Let’s dive into why managing cables effectively is key to any setup.

Enhancing Safety With Cable Sleeves

- Prevents tripping hazards: Loose cables across the floor create a risk of trips and falls.

- Reduces fire risk: Well-organized cables improve air circulation, reducing heat buildup.

- Protects cables: Sleeves shield wires from abrasion, extending their life.

Improving Aesthetics And Reducing Clutter

Unsightly cables can ruin the look of a space. Cable sleeves offer a neat solution. They bundle cables together, hiding them from view. This not only improves the appearance of your area but also makes cleaning around cables simpler. With clutter reduced, finding and accessing cables becomes a breeze.

| Without Cable Management | With Cable Sleeves |

|---|---|

| Messy and hazardous environment | Clean and safe surroundings |

| Difficult to locate and manage cables | Easy identification and access to cables |

| Poorly protected wires with shorter lifespans | Durable cables due to added protection |

Cable Sleeves: Types And Materials

Neat cables mean more than just an organized space. Cable sleeves protect wires from damage and reduce clutter. They come in various types and materials, each with specific benefits. Exploring these options helps select the best sleeve for your cables.

Exploring Varieties: From Braided To Heat Shrink

Different setups require different sleeves. We have braided, heat shrink, and more. Let’s dive into these common types:

- Braided Sleeves – Flexible and durable, perfect for spaces that need airflow.

- Heat Shrink Sleeves – They fit tightly around cables after heat application. Ideal for a snug protection.

- Split Sleeves – These come split for easy cable insertion. Solid for frequent adjustments.

- Zip-Up Sleeves – Use a zipper to enclose cables. Great for quick access and cable management.

Material Choices: Pet, Nylon, And Neoprene

Material matters in protection and durability. Let’s compare PET, Nylon, and Neoprene:

| Material | Features | Benefits |

|---|---|---|

| PET | Lightweight, flexible | Resists chemicals, cuts, and abrasions |

| Nylon | Exceptionally strong, stretchy | High abrasion resistance, easy to apply |

| Neoprene | Elastic, soft | Great for environments with temperature fluctuations |

Choose the right material for the specific needs of your environment. PET for light, versatile sleeves. Nylon for areas needing durability. Neoprene handles temperature well. Each choice ensures long-lasting cable protection.

Preparation Steps Before Installing Cable Sleeves

An organized workspace not only looks great but also enhances functionality. If you’re diving into the world of cable management, using cable sleeves can transform a tangled mess into a sleek system. Before starting this project, prepare properly to ensure a smooth installation. Let’s walk through the initial preparation steps.

Gathering Tools And Materials

Gather all the necessary tools and materials before beginning. This will save time and avoid interruptions. Here’s what you’ll need:

- Measuring tape: to measure cable lengths accurately.

- Scissors or a sharp blade: to cut sleeves cleanly.

- Lighter or heat gun: if using heat-shrink tubing.

- Labels or markers: to tag cables for easy identification.

- Cable sleeves: the main material for bundling wires.

Planning Your Cable Layout

A well-thought-out plan is vital for an effective cable management system. Sketch your workspace and map out:

- The route each cable will take.

- Where cables will bundle together.

- Access points for devices and outlets.

This plan ensures you use the right length and type of sleeves for your setup.

Credit: m.youtube.com

Step-by-step Guide To Sleeving Cables

Cable sleeving can transform the mess behind your desk into a neat showcase. It’s simple, just follow these steps to protect your cables and enhance airflow. Let’s dive into the process of cable sleeving.

Measuring And Cutting Sleeves

Start by measuring the cables you plan to sleeve. Measure their length for precise sleeve cutting. Factoring in a little extra is wise for a perfect fit.

- Use a tape measure for length.

- Add an extra centimeter to each measurement.

- Cut the sleeve with scissors or a cutter.

Ensure that each piece is cut straight to avoid fraying.

Threading Cables And Sealing Ends

Threading your cables through the sleeves comes next. Use patience and care to prevent damage.

- Begin at one end and push the cable through.

- Maintain tension on the sleeve as you go.

- For multiple wires, bundle them neatly before sleeving.

After threading, seal the ends. Heat shrink tubing works best. Slide it over the sleeve’s end and apply heat evenly until it shrinks securely in place.

| Step | Action |

|---|---|

| 1. Measure | Measure cables, add extra length. |

| 2. Cut | Cut with precision, consider a margin. |

| 3. Thread | Push cable through, maintain tension. |

| 4. Seal | Apply heat shrink, use heat evenly. |

Keep tools at hand and follow each step carefully. Soon, you will have professionally sleeved cables.

Maintenance And Upkeep Of Sleeved Cables

Keeping sleeved cables in top condition ensures longevity and performance. Regular cleaning and inspection help prevent damage and maintain aesthetics. Learn how to care for your sleeved cables properly with these simple strategies.

Regular Cleaning Tips

Dust and dirt can accumulate quickly. Follow these steps to keep cables pristine:

- Power down devices before cleaning to avoid electrical hazards.

- Use a soft cloth or brush to gently remove dust from sleeves.

- For tougher grime, a damp cloth with mild soap works well.

- Avoid harsh chemicals that can damage the sleeve material.

- Let cables dry completely before reconnecting devices.

Inspection And Replacement Strategies

Consistent inspection helps identify issues before they worsen. A methodical approach is key:

- Inspect cables for fraying, cuts, or tears during cleaning.

- Check for discoloration or heat damage, signs of electrical problems.

- Test cables for flexibility as stiffness can indicate inner damage.

- Replace sleeves or cables that show significant wear or damage.

Tag replacement dates on cables to keep track of their lifespan.

| Cable Inspection | Action Required |

|---|---|

| No damage | Continue regular maintenance |

| Minor wear | Monitor closely for changes |

| Significant damage | Replace immediately |

Advanced Techniques And Customizations

Exploring the world of cable management, you’ll find advanced techniques and customizations that can revolutionize the way you organize and protect your wires. From using color to sort cables to crafting your own sleeves, the possibilities are endless. Let’s dive deeper into how to master these skills for a neat and personalized setup.

Color Coding For Easy Identification

Color coding your cables is not just about aesthetics; it’s a practical way to stay organized. Identify each type of cable at a glance, saving time and reducing frustration.

- Assign a color to different cable types.

- Use matching sleeve colors for quick recognition.

- Label each sleeve if colors repeat for different uses.

Apply this technique in complex setups, such as home theaters, gaming rigs, or data centers.

Diy Cable Sleeves For A Personal Touch

Creating your own cable sleeves adds a unique flair. Choose materials that reflect your style and the needs of your setup.

- Pick a durable material like paracord or fabric.

- Measure your cables, leaving extra room for bends and connections.

- Cut the material to length and carefully seal the ends.

Get creative with patterns or textures that stand out or blend with your décor.

| Material | Qualities | Best Use |

|---|---|---|

| Paracord | Flexible and strong | Gaming setups |

| Fabric | Soft and customizable | Home offices |

Credit: www.spacetv.co.za

Frequently Asked Questions For How To Use Cable Sleeves

How Do Cable Sleeves Work?

Cable sleeves bundle multiple wires or cables together, protecting them from abrasion and environmental factors while improving aesthetics and organization. They are easily applied by threading cables through the flexible material.

What Is The Point Of Cable Sleeves?

Cable sleeves protect wires from damage, manage cable clutter, and improve aesthetic appeal by organizing multiple cables into a single sleeve. They also enhance safety by reducing tripping hazards.

How Do You Use A Cable Management Sleeve?

Gather cables and align them. Slide the sleeve over the cables, adjusting for a snug fit. Secure the sleeve’s ends if necessary. Trim excess material for a tailored look, ensuring easy access and maintenance for your cable setup.

Are Cable Sleeves Necessary?

Cable sleeves are not essential but recommended for wire organization, protection, and aesthetics. They prevent tangling and reduce wear, extending cable life.

What Are Cable Sleeves Used For?

Cable sleeves are utilized to organize, protect, and conceal wires, preventing tangling and damage while enhancing aesthetics.

How Do You Install Cable Sleeves?

Wrap the cable sleeve around cables or wires; secure ends with heat shrink or cable ties for a snug, tidy fit.

Can Cable Sleeves Prevent Wire Damage?

Yes, cable sleeves can significantly reduce wire damage by providing a protective layer against abrasion and environmental factors.

Are Cable Sleeves Reusable?

Many cable sleeves are adjustable and reusable, allowing for repeated use when rerouting or changing cable setups.

What Materials Are Cable Sleeves Made Of?

Cable sleeves are typically made from durable materials like neoprene, nylon, PET (polyethylene terephthalate), or silicone.

Do Cable Sleeves Come In Different Sizes?

Yes, cable sleeves are available in various lengths and diameters to accommodate different bundle sizes and installation needs.

Conclusion

Wrapping up, mastering cable sleeves enhances both function and aesthetics. This simple guide empowers you to protect wires effectively and boost organization. Embrace the clarity cable sleeves offer, and enjoy a tidier, safer space. Remember, a well-managed cable system is just a sleeve away.